Komatsu Excavator Bucket Teeth for PC200

We are specialized in the design and manufacture of all kinds of casting parts, such as excavator Teeth, Tips, adaptors

Basic Info.

| Model NO. | PC200 |

| Heat Treatment | Quench |

| Transport Package | Standard Export Wooden Case |

| Specification | Alloy Steel |

| Trademark | ZP |

| Origin | China |

| HS Code | 843149900 |

| Production Capacity | 5000 PCS/Month |

Product Description

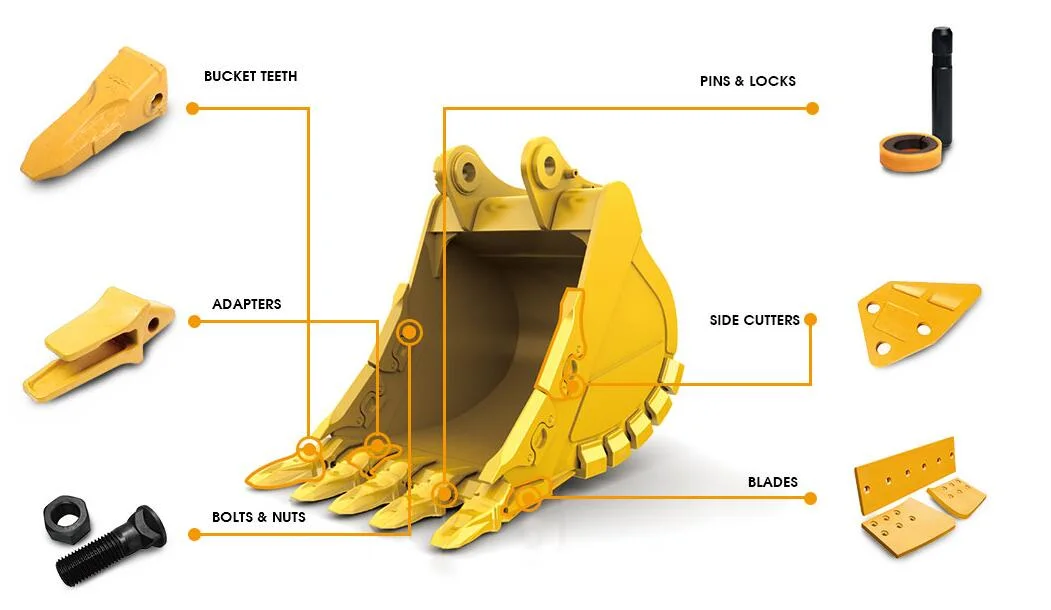

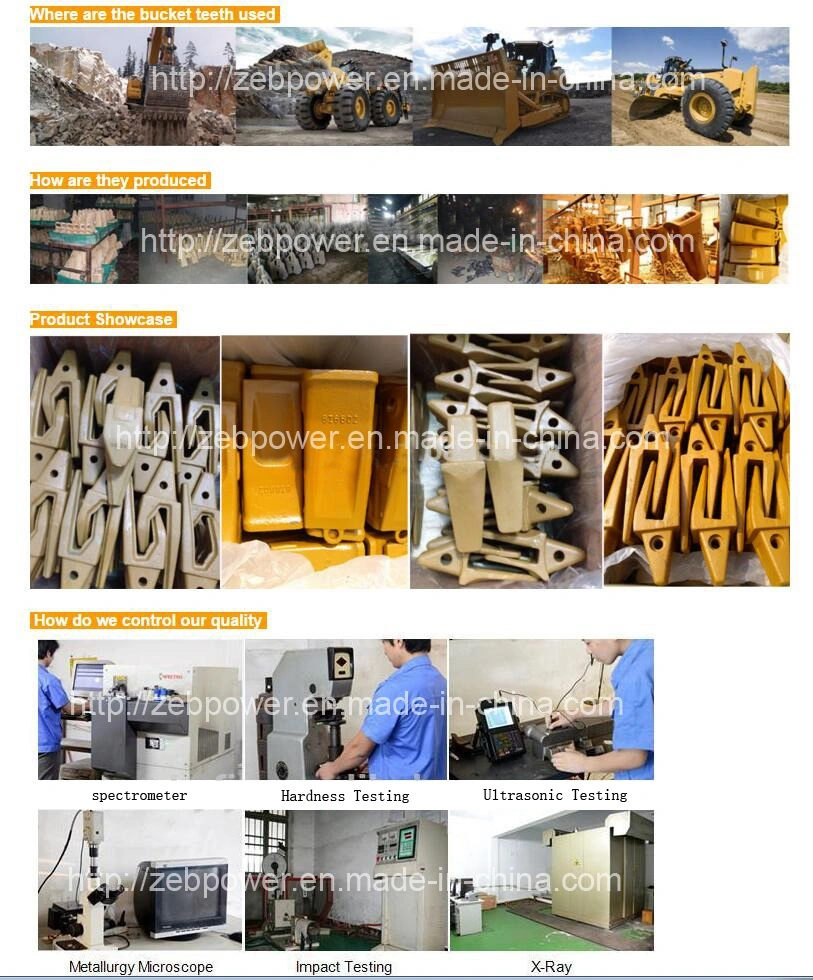

We are specialized in the design and manufacture of all kinds of casting parts, such as excavator Teeth, Tips, adaptors and side cutters. Main products are all kinds of high-manganese steel, wear-resistant steel and alloy steel parts. We have more than one thousand kinds of products widely used in construction machinery field,such as Caterpillar,Komatsu,Esco,Doosan,Volvo,Hyundai,Hitachi,Kobelco,JCB,CASE,etc.What we supplied for ground engaging tools:

| Main Information | ||||||

| Machine type: | Excavator, Loader,Bulldozer,etc. | |||||

| Brands: | Komatsu, Caterpillar, Hitachi, Volvo, Case, John Deer, Doosan, Hyundai, Kobelcom, JCB, Yanmar, Terex, XGMA, LIUGONG, SANY, LONGKING, BOBCAT. | |||||

| Heat treatment: | Quenching and tempering treatment | |||||

| Work condition: | With excellent elongation and tensile strength, | |||||

| suitable for many different hard working conditions. | ||||||

| Mecanical Performance | ||||||

| Material No. | Product | Impact Toughness (ak/JC m2) | Hardness HRC | Tensile Strength | Elongation | Material Class |

| ALZG1# | Adapter, Side Cutter, Protectors | >=15 | 36-40 | >=1300 | >=4 | Standard |

| ALZG2# | Teeth/Loader Teeth | >=15 | 48-52 | >=1500 | >=4 | |

| ALZG3# | Adapter(>20kg) | >=20 | 40-46 | >=1350 | >=5 | Hight |

| ALZG5# | Teeth(>20kg) | >=16 | 51-54 | >=1550 | >=5 | |

Advantages:

- Penetration: Improved penetration reduces load on the engine, transmission, tires and hydraulic system.

- Ingenious: Beautiful durable rock chisel k bucket teeth, special design, more durable than normal bucket teeth.

- Wearlife: Extra material designed, maximize wearlife and impact resistance.

- Sharpness: Self-sharping design, better penetration, less stress on the machine, less oil consumption.

- Hardness (HRC): 51-54, high quality, longer wearing life, Up to 250 hours, stronger, create productivity.

- Save up 25% cost

previous:

Weld

Send to us